Buck Boost Regulator using XL6009 with Adjustable 3.3V to 12V Output Voltage

Buck-Boost regulator is made using two different topologies, as the name suggests, it consists of both buck and boost topology. We already know that Buck Regulator Topology provides a lower magnitude of output voltage than the input voltage, while a Boost Regulator Topology provides a higher magnitude of output voltage than the provided input voltage. We have already built a 12V to 5V Buck Converter and a 3.7V to 5V Boost converter Circuit using the popular MC34063. But at times, we might need a circuit that can both work as a buck and a boost regulator.

Say, for example, if your device is powered using a lithium battery, then the input voltage range will be between 3.6V to 4.2V. If this device needs two operating voltage 3.3V and 5V. Then you need to design a buck-boost regulator that will regulate the voltage from this lithium battery into 3.3V and 5V. So, in this tutorial, we will learn how to build a simple buck-boost regulator and test it on a breadboard for the ease of building. This regulator is designed to work with a 9V battery and can provide a wide output voltage ranging from 3.3V to 12V with a maximum output current of 4A.

Components Required

Xl6009

10k preset

33uH inductor - 2pcs

1n4007 - 2pcs

SR160 - 1pc (for max 800mA output)

10uH inductor

100uF Capacitor

1000uF capacitor -2pcs

1uF ceramic or polyester film capacitor

9V power source (battery or adapter)

Breadboard

Wires for breadboard.

XL6009 Buck-Boost Regulator IC

There are many ways to build a buck-boost circuit, for the sake of this tutorial, we will be using the famous XL6009 DC/DC Converter IC. We have selected this IC because of its ease of availability and beginner-friendly nature. You can also check the article on how to select switching regulator IC to help you with other regulator selection for your switching designs.

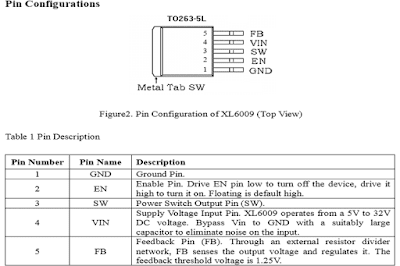

The main component is the switching regulator XL6009. The pinout of XL6009 and the specifications are shown in the below image.

Buck-Boost regulator is made using two different topologies, as the name suggests, it consists of both buck and boost topology. We already know that Buck Regulator Topology provides a lower magnitude of output voltage than the input voltage, while a Boost Regulator Topology provides a higher magnitude of output voltage than the provided input voltage. We have already built a 12V to 5V Buck Converter and a 3.7V to 5V Boost converter Circuit using the popular MC34063. But at times, we might need a circuit that can both work as a buck and a boost regulator.

Say, for example, if your device is powered using a lithium battery, then the input voltage range will be between 3.6V to 4.2V. If this device needs two operating voltage 3.3V and 5V. Then you need to design a buck-boost regulator that will regulate the voltage from this lithium battery into 3.3V and 5V. So, in this tutorial, we will learn how to build a simple buck-boost regulator and test it on a breadboard for the ease of building. This regulator is designed to work with a 9V battery and can provide a wide output voltage ranging from 3.3V to 12V with a maximum output current of 4A.

Components Required

Xl6009

10k preset

33uH inductor - 2pcs

1n4007 - 2pcs

SR160 - 1pc (for max 800mA output)

10uH inductor

100uF Capacitor

1000uF capacitor -2pcs

1uF ceramic or polyester film capacitor

9V power source (battery or adapter)

Breadboard

Wires for breadboard.

XL6009 Buck-Boost Regulator IC

There are many ways to build a buck-boost circuit, for the sake of this tutorial, we will be using the famous XL6009 DC/DC Converter IC. We have selected this IC because of its ease of availability and beginner-friendly nature. You can also check the article on how to select switching regulator IC to help you with other regulator selection for your switching designs.

The main component is the switching regulator XL6009. The pinout of XL6009 and the specifications are shown in the below image.

The metal tab is internally connected with the Switching pin of the XL6009 driver ic. The pin description is also given in the above table. The important technical specifications of XL6009 IC is given below

Features

Wide 5V to 32V Input Voltage Range

Positive or Negative Output Voltage Programming with a Single Feedback Pin

Current Mode Control Provides Excellent Transient Response

1.25V Reference Adjustable Version

Fixed 400KHz Switching Frequency

Maximum 4A Switching Current

SW PIN Built-in Over Voltage Protection

Excellent Line and Load Regulation

EN PIN TTL Shutdown Capability

Internal Optimize Power MOSFET

High Efficiency of up to 94%

Built-in Frequency Compensation

Built-in Soft-Start Function

Built-in Thermal Shutdown Function

Built-in Current Limit Function

Available in TO263-5L Package

The above specification chart is showing that the minimum input voltage of this driver IC is 5V and the maximum is 32 Volt. Also, as the switching frequency is 400 kHz, it opens up possibilities to use smaller inductors for switching related purposes. Also, the driver IC supports a maximum of 4A output current which is great to cover up many high rated current related applications.

Buck-Boost Converter Circuit using XL6009

For any switching regulator, the Inductor and the capacitor are the main components. The position of the Inductor and the capacitor in the circuit is very essential to provide the required power to the load during switch on and off condition. In this case, two inductors (l1 and L4) are used that will support buck and boost function individually in this switching circuit. The 33uH inductor that is L1, is the inductor which is responsible for the Buck mode of operation whereas the Inductor L2 is used for the Boost mode inductor. Here I have wound my own inductor using a ferrite core and enameled copper wire. If you are new to making your own inductor, you can check this article on the basics of inductor and Inductor coil design to get started. Once you have built your inductor, you can check its value using an LCD meter or if you don’t have an LCR meter, you can use your oscilloscope to find inductor value using the resonant frequency method.

The input capacitors, C1 and C2 are used to filter transients and ripple from the external battery or the power source. The capacitor C3, 1uF, 100V is used for isolating these two inductors. There is a Schottky diode SR160 which is a one ampere, 60V diode used for converting the switching frequency cycle to a DC and the capacitor 1000uF, 35V is the filter capacitor used for filtering the output from the diode.

As the Feedback threshold voltage is 1.25V, the voltage divider can be set according to this feedback voltage for configuring the actual output. For our circuit, we have used a pot (R1) and a resistor (R2) to provide the feedback voltage.

R1 is a variable resistor which is used for setting the output voltage. The R1 and R2 form a voltage divider that provides feedback to the driver IC XL6009. 10uH inductor L4 and 100uF capacitor C3 are used as an LC filter.

Buck-Boost Converter Construction and Working

Other than the Inductor, all the components should be available easily. The XL6009 IC is not breadboard friendly. Hence, I have used the dotted board to connect the pins of XL6009 to male header pins as shown below.

Build the inductor as discussed earlier and create your circuit. I have used a breadboard to make things easy but a perf board is recommended. Once complete my circuit on breadboard looked like this.

The output voltage can be set from 3.3V to 12V using the potentiometer. Technically, the circuit can be designed for a high output current as much as 4A. But, due to the limitation of the output diode, the circuit is not tested in a full load. The output load is set to a decent value of approximately 700-800mA of current. You can change the output diode to increase the output current if required.

To test our power supply circuit, we have used a multimeter to monitor the output voltage and for the load, we have used the DC electronic load something similar to what we build earlier. If you do not have an electronic load, you can use any load of your choice and monitor current using a multimeter. The complete testing video is given at the bottom of this page.

It is also noticed that the output voltage is a bit fluctuating in a +/-5% margin. This is due to the high DCR value of inductors and the unavailability of the heat sink in the XL6009. Adequate heat sink and proper components can be useful for stable output. Overall, the circuit is working quite operational and performance is satisfactory. If you have any questions, leave them in the comment section, you can also use our forums for other technical questions.

https://lnkload.com/2vb7U

No comments:

Post a Comment